Marking is one of the important operations in engineering division. Accuracy & Quality of product mostly depending upon it. For performing this operation several tools are used Known as marking tools as follows.

MARKING BLOCK:- It is of two types

1. Ordinary

2 Universal type

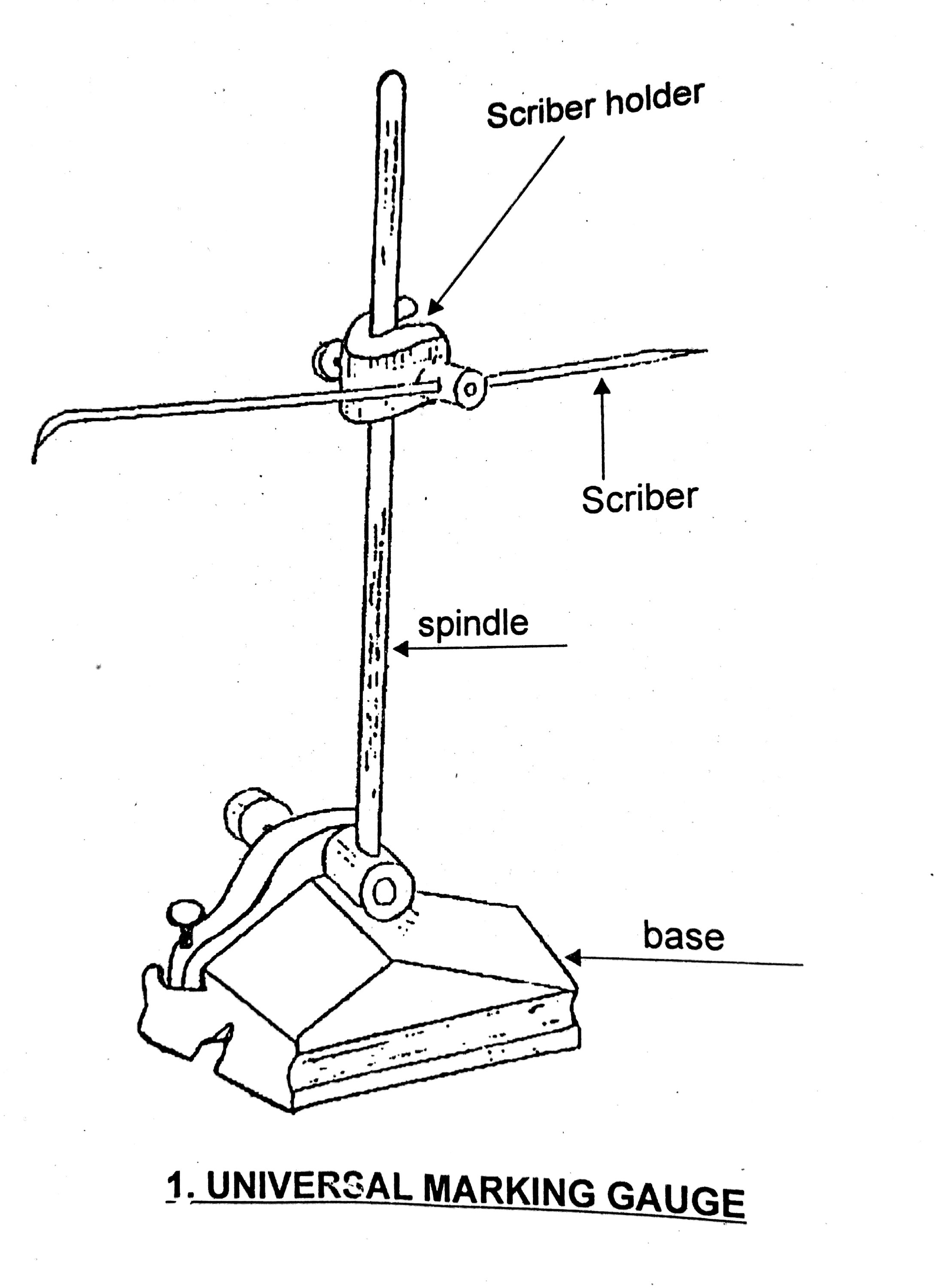

1.Universal type marking block:

1.Universal type marking block:

It consists of a cast iron base, spindle , scriber with clamp, adjusting screw etc. Base carries a Spindle which may be set at any angle. A scriber, which may be set at any angle or height is clamped to the spindle. When marking, it is put on the surface plate, by giving movement to the base, lines can be marked by its scriber on the job as per the drawing given. The other use of this type of gauge is for marking out lines on the round bar by putting them on the “V block. Also it is used to find out the center of a round block, to align the work in the center & to lay out markings on a work piece of any shape.

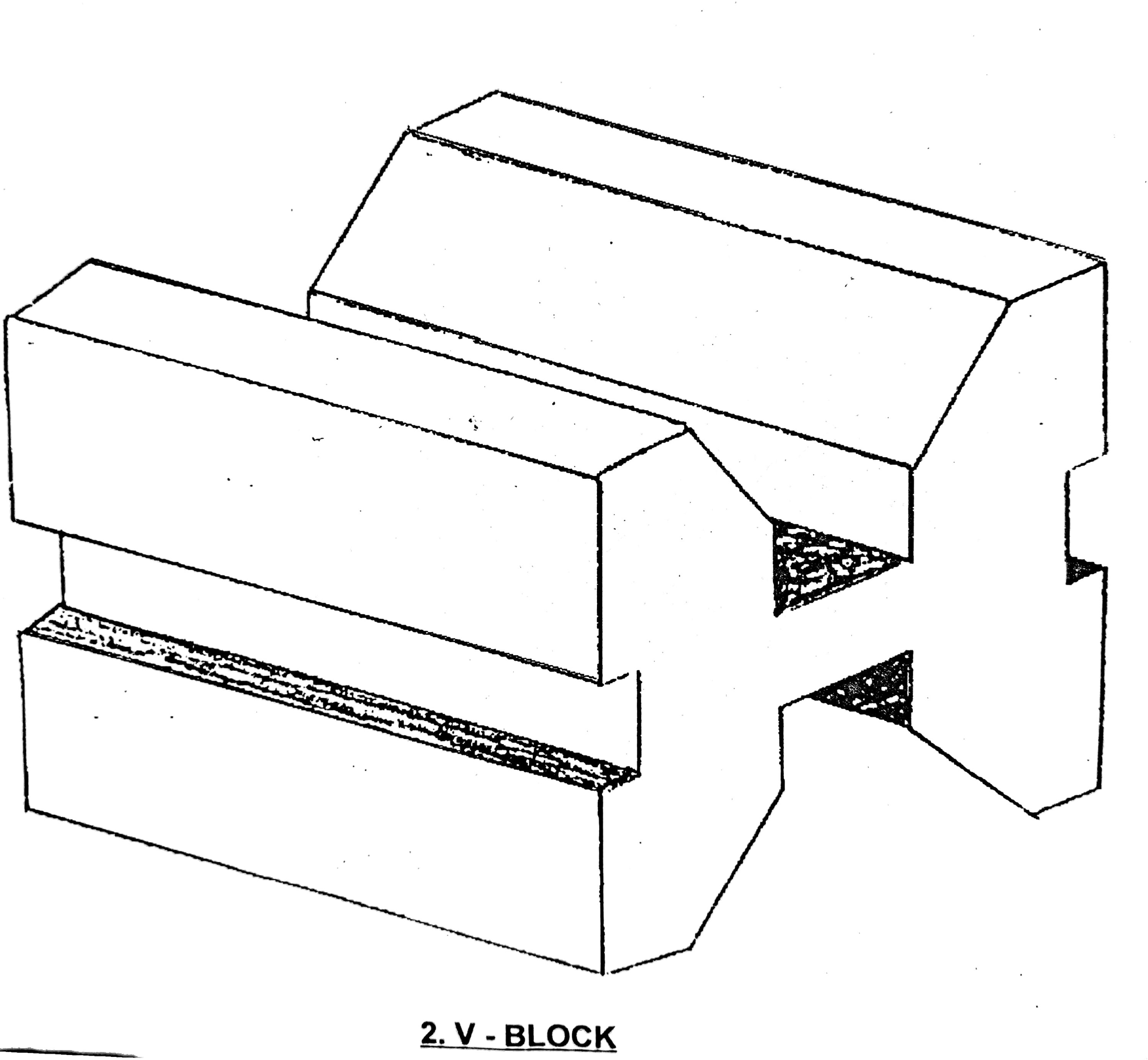

2. ‘V’ BLOCK:

The “V” block is made of cast iron and all of its faces are machined truly. The two opposite side Faces have V grooves & the two have slots. The round bars are held firmly by means of a U- clamp which engaged in slots. It always in pair or in set with U-clamp.

Applications:

1.For finding out center of round bar.

2.For drilling , reaming, taping on round bar .

3. For marking lines & for checking ovality of round bar using Dial test indicator.

3.SURFACE PLATE: it is made of grey cast iron in various sizes. It is usually in square or rectangular and has the top and the adjacent four edges very accurately machined and scraped to form a true flat surface and are brought in square. The casting is ribbed to prevent it from deformation. It is placed horizontally on a firm support whose working height is about 850 m. m. from the reference plan or floor.

USE: It is used to check the trueness of flat surface & to copy the master surface on a work.

4. SCRIBER: It’s around hardened steel piece of about 150 m.m. long & 3 to 5m.m. in diameter. Its one end is sharp pointed but bent. The bent end is used to scratch lines in places where the straightened end can not reach. The ends are sharpened on an oil stone when it’s required.

5.ANGLE PLATE: The angle plate is made of cast iron in different sizes. It has two planed surfaces at a right angle to each other & has various slots in both surfaces to hold the work firmly By means of bolts & clamps. The angle plate is used in conjunction with the surface plate for Supporting work at right angle formarking.

Amazing

Can you be more specific about the content of your article? After reading it, I still have some doubts. Hope you can help me.