Introduction

Ultrasonic machining (USM) is the removal at ultrasonic frequencies[18-20 kilohertz (kHz)] of rough and fragile materials using an axially oscillating method.

The abrasive slurry of B4C or SiC is continuously fed into the machining zone between a soft instrument (brass or steel) and the workpiece during the oscillation. The abrasive particles are, thus, pounded into the surface of the workpiece and allow fine particles to be chipped off it.

Static pressure is exerted on the abrasive grains by the oscillating tool at amplitudes ranging from 10 to 40 μm and feeds down as the material is withdrawn to form the appropriate tool shape.

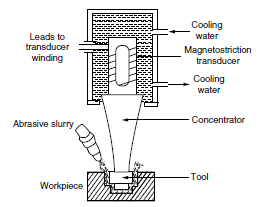

The machining method consists primarily of the feeding structure of the magnetostrictor, concentrator, instrument, and slurry. The magnetostrictor is energized and produces small-amplitude waves at the ultrasonic frequency.

Using the constrictor (mechanical amplifier) that holds the instrument, even a slight vibration is amplified. The abrasive slurry is pumped between the delicate workpiece and the oscillating method. In the instrument-workpiece interface, which preserves the abrasive slurry, astatic pressure is applied.

Mechanical Amplifier

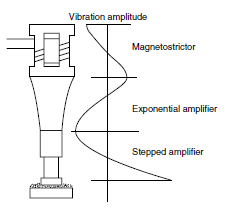

The elongation achieved using a magnetostrictor of length l = 0.5l at the resonance frequency fr is usually 0.001 to 0.1 μm, which would be too small for operational machining applications.

By fitting an amplifier (acoustic horn) into the output end of the magnetostrictor, the vibration amplitude is increased. Larger amplitudes are considered to be acceptable for realistic purposes, usually 40 to 50 μm.

The amplitude amplification can be accomplished by one or more acoustic horns, based on the final amplitude needed. In order to provide the highest vibration amplitude, multiples of one-half of the sound wavelength l in the concentrate (horn) material are made of the duration of the concentrate.

In contrast with the conical and hyperbolic horns, exponential and stepped forms are commonly used because they are easily built and made. With high fatigue strengths of 185 and 150 meganewtons per square meter (MN/m2), aluminum bronze and marine bronze are inexpensive, respectively.

High losses encountered, poor performance (55 %), the resulting heat up, and the need for cooling are the key disadvantages of the magnetostrictive transducer. Higher efficiencies (90-95 %) are feasible with the use of modern USM machines with piezoelectric transformers.

Tool

In contrast with the conical and hyperbolic horns, exponential and stepped forms are commonly used because they are easily built and made. Including high fatigue strengths of 185 and 150 meganewtons per square meter (MN/m2), aluminum bronze and marine bronze are inexpensive, respectively. High losses encountered, poor performance (55 percent), the resulting heat up, and the need for cooling are the key disadvantages of the magnetostrictive transducer. Higher efficiencies (90-95 percent) are feasible with the use of modern USM machines with piezoelectric transformers.

Abrasive Slurry

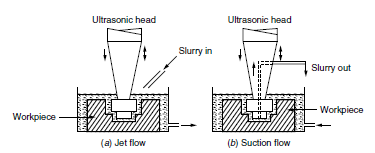

Typically 50 percent (by volume) of fine abrasive grains (100-800 grit number) of boron carbide (B4C), aluminum oxide (Al2O3), or silicon carbide (SiC) in 50 percent water are composed of the abrasive slurry. The abrasive slurry flows between the oscillating instrument and the workpiece.

The abrasive particles are hammered onto the workpiece surface under the influence of the static feed force and ultrasonic vibration, inducing mechanical chipping of minute particles. At a rate of 25 liters per minute (L/min), the slurry is pumped through a nozzle near the tool-workpiece interface.

As processing continues, as the particles wear and break down, the slurry becomes less effective. The estimated life expectancy is between 150 and 200 hours (h) of ultrasonic penetration. In order to ensure adequate flushing of debris, the slurry is constantly fed to the machining zone which keeps the suspension cold during machining. USM’s output depends on the way the slurry is fed to the cutting field.

Material removal process

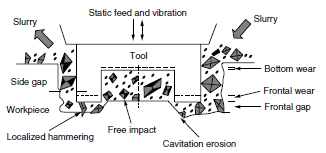

USM’s content replacement process, which requires three related actions:

- Mechanical abrasion of the abrasive grains caught between the vibrating device and the neighboring work surface by localized direct hammering.

- The free-impact microchipping of particles that travel through the machining distance and hit the workpiece at random points.

- Erosion of the working surface by cavitation in the slurry stream.

Less than 5 percent of the overall material extracted is stated to be the relative contribution of the cavitation effect. Of all materials, the main process involved in USM is direct hammering. Weak and porous materials such as mild steel are also first deformed plastically and are then withdrawn at a lower cost.

The machining rate is high in the case of hard and brittle materials such as glass and it is also easy to note the role played by free effects. The method of corrosion is implemented when machining porous materials such as graphite.

In USM, the rate of material removal depends, first of all, on the level of vibration of the instrument, the static friction, the machined area scale, and the material of the abrasive and workpiece.

The rate of material removal and hence USM machinability depends on the criterion of brittleness, which is the ratio of shearing to a material’s breaking strength.

Factors affecting material removal rate

Tool oscillation

Of all the method variables, the amplitude of the tool oscillation has the greatest effect. With a spike in the amplitude of the tool vibration, the material removal rate increases. At the interface between the instrument and the workpiece, the vibration rate defines the frequency of the abrasive particles.

Under certain conditions, at greater amplitudes, the kinetic energy increases, which boosts the mechanical chipping operation and thereby increases the rate of elimination.

Higher vibration intensity can lead to splashing, which causes the amount of active abrasive grains to decrease and results in a decrease in the rate of material removal.

Abrasive grains

The grain size and the amplitude of the vibration both have a similar effect on the rate of removal. At larger grain sizes, the removal rate increases before the scale exceed the amplitude of vibration, at which point the rate of material removal decreases.

There is an issue of abrasive regeneration in the machining gap where the grain size is high relative to the vibration amplitude. B4C achieves better removal speeds than silicon carbide (SiC) when machining a soda glass workpiece due to its higher hardness.

When machining glass, the rate of material removal obtained for silicon carbide is around 15 percent lower, 33 percent lower for tool steel, and about 35 percent lower for sintered carbide.

Workpiece impact-hardness

The machining rate is influenced by the instrument strength ratio to the hardness of the workpiece. The higher the ratio in this respect, the lower the rate of content removal would be. For this purpose, for USM instruments, soft and tough materials are recommended.

Tool shape

The tool form and area influence the machining rate. Owing to the issue of accurately spreading the abrasive slurry over the whole machining region, an improvement in the tool area lowers the machining rate. A narrow rectangular shape yields a higher machining rate than a square cross-sectional one for the same machining area.

The increase in the static feed pressure raises the machining rate until there is a limiting condition, above which there is no further increase. The explanation behind such a pattern is due to the disruption of the instrument’s oscillation activity at higher forces where it is predicted that lateral vibrations will occur.

Applications

- Drilling and coring

- Ultrasonic sinking and contour machining

- Production of EDM electrodes

- Ultrasonic polishing

- Micro-ultrasonic machining

You really make it appear so easy with your presentation but I to find this matter to be actually something that I think

I might by no means understand. It kind of feels too complex and very wide for me.

I’m looking ahead for your subsequent put up, I’ll attempt to get the cling of it!

Great article, totally what I wanted to find.

Thanks for some other wonderful post. Where else could anybody get that type

of info in such a perfect method of writing? I have a presentation subsequent week, and I am at the

look for such information.

This website was… how do I say it? Relevant!!

Finally I have found something which helped me. Thanks a

lot!

I really like your blog.. very nice colors & theme.

Did you create this website yourself or did you hire someone to do it for you?

Plz respond as I’m looking to create my own blog and would like to know where u got

this from. many thanks

Wow, this article is pleasant, my younger sister is analyzing these kinds of things,

therefore I am going to tell her.

Excellent web site you have got here.. It’s difficult to

find excellent writing like yours these days. I seriously appreciate individuals like you!

Take care!!

My brother suggested I might like this blog. He was totally right.

This post actually made my day. You can not imagine

just how much time I had spent for this info! Thanks!

Hi there everybody, here every person is sharing such experience, therefore it’s

pleasant to read this blog, and I used to visit this website weekly.

Wonderful blog! I found it while surfing around on Yahoo News.

Do you have any tips on how to get listed in Yahoo News?