Machining removes some parts of the workpieces to change them into final parts, as stated earlier. Traditional, also called conventional, machining involves the presence of a tool that is tougher to machine than the workpiece. This tool should be penetrated to a certain depth inside the workpiece. In addition, it is responsible for shaping or producing the appropriate shape for a relative motion between the tool and the workpiece.

The lack of any of these components in any machining phase, such as the absence of contact with the tool-workpiece or relative motion, makes the process unconventional.

Machining by Cutting

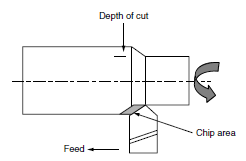

The tool is penetrated to the depth of the cutting in the workpiece material during machining by cutting. A relative (main and feed) movement determines the necessary geometry of the workpiece.

In this respect, cylindrical parts are created by turning, flat surfaces are developed by shaping and milling, while holes of various diameters are produced by drilling.

A specific number of cutting edges of a known geometry are required for instruments. In the form of chips, which are visible to the human eye, the cutting operation eliminates the machining allowance.

The shape of the workpiece may be created by shaping when the cutting tool has the produced contour of the workpiece through machining by cutting.

In accordance with the tool feed in-depth as seen in Image, a relative motion is required to generate the chip (main motion). Most of the accuracy of the surface profile depends on the precision of the form-cutting tool. Several movements that accomplish the chip forming process (main motion) and the motion of the point of contact along the surface may also create a surface (feed motion).

A similar pattern of surface generation through cutting is given in the figure. The combined type and generation cutting principles are followed by slot milling, shown in the figure.

Machining by abrasion

The word abrasion machining typically defines processes whereby a multitude of rough, angular abrasive particles or grains (also called grits) which may or may not be bonded to shape an instrument of definite geometry are excluded from the machining allowance.

In comparison to metal cutting processes, the individual cutting edges are randomly focused during abrasive machining, and the engagement depth (the undeformed chip thickness) is limited and not equal to all abrasive particles that are in contact with the material at the same time.

The cutting edges (abrasives) are used during the finishing procedures to remove a small design and manufacturing allowance through the MA action.

In most cases, the substance is removed in the shape of minute chips that are transparent (Kaczmarek, 1976). During grinding, honing, and superfinishing processes that use either solid grinding wheels or tends to stick in the form of bonded abrasives, the MA operation is adopted. In addition, loose abrasives are used as devices for lapping, polishing, and buffing.

Nontraditional Machining

The dramatically enhanced thermal, chemical and mechanical properties of the modern manufacturing materials have rendered it difficult to use conventional cutting and abrasion machining methods to machine them.

This is because conventional machining is more commonly based on material removal using devices that are more difficult than the workpiece. The high ratio of the size of grinding wheel worn per unit volume of metal extracted, for instance, allowed classical grinding ideal for the manufacture of polycrystalline diamond (PCD) profile tools only to a small degree.

The increased cost of ceramic and composite machining and the harm sustained during machining are significant hurdles to the introduction of these products. More complex forms, low-rigidity structures, and micromachined components with close tolerances and precise surface quality are also required in addition to exotic materials.

In machining these materials, conventional machining techniques are often inefficient. Fresh processes are built to fulfill these demands. In the aerospace, automotive, tool, die, and mold-making industries, these techniques play a significant role.

Mechanical machining

Typical examples of single-action, mechanical, nontraditional machining processes are ultrasonic machining (USM) and water jet machining (WJM). Machining happens in USM by MA while cutting is adopted in the case of WJM using a fluid jet. Strong grains suspended in the abrasive slurry in the former are the machining medium, whereas a liquid is used in the WJM process.

The application of abrasives to the fluid jet increases cutting during ice jet machining in the event of abrasive water jet machining (AWJM) or ice crystals (IJM).

Thermal machining

Thermal machining, by melting or vaporizing the workpiece stock, eliminates the machining allowance. During machining, many secondary phenomena related to surface quality occur, such as microcracking, heat-affected zone forming, and striation.

Plasma during electro-discharge machining (EDM) and plasma beam machining (PBM), photons during laser beam machining (LBM), electrons for electron beam machining (EBM), or ions for ion beam machining (EBM) can be the source of heat needed for material removal (IBM).

The machining medium for both of these processes is different.

Chemical and electrochemical machining

In order to extract the machining allowance by ions in an etchant, chemical milling (CHM) and photochemical machining (PCM), also called chemical blanking (PCB), use a chemical dissolution (CD) operation. In order to extract the machining allowance using ion transfer in an electrolytic cell, electrochemical machining (ECM) uses the electrochemical dissolution (ECD) phase.

Hybrid Machining

It is possible to achieve technological enhancement of machining processes by combining various machining actions or stages to be used on the removed material.

With the respective machining phases of electro-discharge (ED) in electro-discharge machining (EDM) or ECD in ECM, a mechanical conventional single cutting or MA action process can be combined.

The main reason for such a combination and the development of a hybrid machining process is to make use of the combined advantages and, when applied individually, to avoid or reduce certain adverse effects that the constituent processes produce.