Fitting is the assembling together of parts and removing metal to secure the necessary fitting.

In general, fitting may be consists of chipping, filing, scraping, drilling, reaming, tapping.cornering etc.

MEASURING TOOLS (FITTERY)

INTRODUCTION: Measurement has played an important role in scientific as well as in technological advancement.

Measuring instruments, tools & various gauges are used for measurement and inspection to establish the manufacturing accuracy of the parts.

A measuring instrument is a device that may be used to obtain a dimensional or surface measurement directly or indirectly.

Common measuring instructions are as below.

1. STEEL RULE: It is the most useful measuring tool on shop floor for taking linear measurements of blanks & articles to an accuracy from 1.0 to 0.5 m.m.

It consists of stiff, straight strip of hardened stool having line graduations of standard unit of length.

It is usually marked in both inches & centimeters.

Steel rule is used to set the dimensions.

TYPES:

Following are the common types of steel rule.

1. Flat Steel rule

2. Four fold rule

3. Hook rule

4. Shrink rule

5 Rule depth gauge etc.

Rules can be made from stainless steel, brass,wood, plastic, aluminium, canvas etc.

CONVERSION TABLE:

1 cm. = 10 m.m

1″ = 25.4m.m = 2.54 c.m. = 0.0254 m.

1 m = 39.37″ = 3.28′ = 1.094 yd

1’=12″

1 m.m=0.1 c.m

1micron= 0.001 m.m.

2.VERNIER HEIGHT GAUGE: It is used to measure the height and marking out lines on a part to an accuracy of 0.02 m.m &0,001″ in metric & British system of measurement respectively.

It consists of a heavy base a graduated column, a sliding head with vernier scale, sliding jaws with scriber etc. It is available in various sizes like 0-200m.m.

Before using a V.H.G check its zero line. On this position of scriber, the zero line of main & vernier scales must be in a straight line and the sharp edge of scriber must be touched with surface plate. For marking out lines the scriber is set for the required height, then the lines are scribed by moving the scriber along with the workpiece.

THE LEAST COUNT OF THE V.H.G.:

Value of the smallest division on the main scale/Total no. of divisions on vernier scale

=1 m.m. / 50

= 0.02 m.m. (METRIC)

in British system the least count of V.H.G. is 0.001″

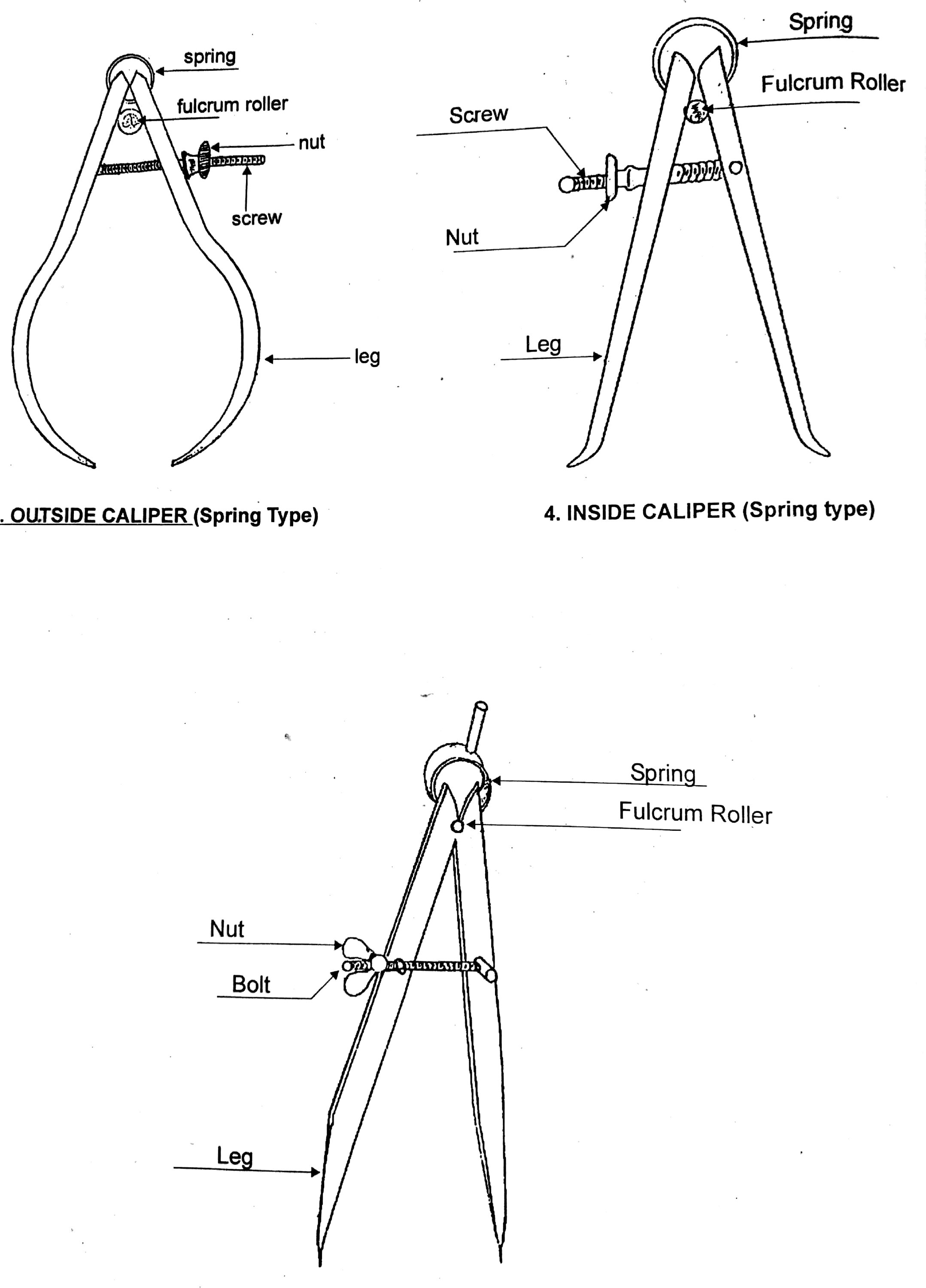

3.CALIPERS: A caliper is used to transfer & compare a dimension.

The measurement can not be taken directly so, it is an indirect measuring instrument, made from carbon steel or tool steel by hardening & tempering to both ends of its measuring legs.

TYPES:

There are mainly two types.

1.Fim joint caliper

2. Spring joint caliper

In firm joint caliper, both of its similar legs are joint by pining tightly. So that, it is so much harder in using and operating. While in spring joint caliper, an adjusting screw & nut keep the legs harder in proper position.

Also it can be opened & closed quickly and accurately.

Thus it can give a quick & accurate reading.

Calipers are further divided as

1. Out-side caliper for measuring out-side diameter of round jobs.

2. In-side caliper for measuring in-side diameter of hollow round jobs.

3. Divider for marking circle or half circle on jobs.

4. Hermaphrodite caliper or odd leg caliper.

That is wonderful. Keep this going. Really helpful for mechanical engineers who are eager to read something which can be helpful in their professional field.

Good content bro, keep it ur work.